As far as rapid prototyping services are concerned, designers and manufacturers have to choose between two primary types of production methods, namely CNC machining and 3D printing. As both have their own set of advantages and disadvantages, the choice can be confusing if you don’t really know what those are exactly.

Once you have gone through this brief comparison between CNC machining services and 3D printing services, choosing between the two should not feel too difficult at all. You will learn that while CNC services might have more advantages on its side, 3D printing too has applications that are beyond the capabilities of traditional prototype manufacturing methods of any kind. Let’s get into the comparison to make more sense of everything.

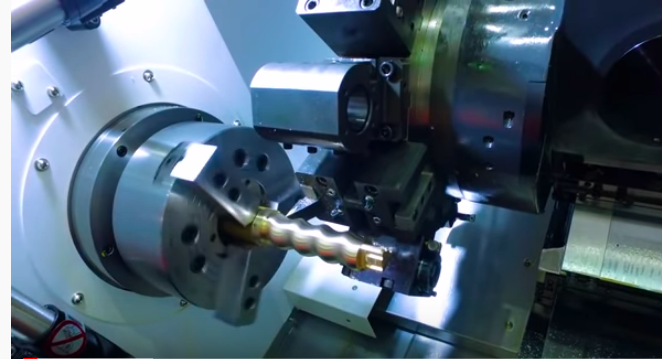

CNC Machining Vs. 3D Printing: Subtractive vs Additive Manufacturing

The core difference between CNC machining and 3D printing is that the former is a subtractive manufacturing method, while the latter is additive by definition and in practice.

CNC Machining: The “blank” is a block or chunk of material that has been chosen for the particular prototype machining project. This blank is then cut, shaped and molded automatically, in accordance with the computerized numeric control (CNC) files supplied by the prototype designer.

As the spinners and cutters of the machine remove or subtract material from the original blank to achieve the desired effect, CNC machining is considered to be a subtractive method for prototype machining.

3D Printing: 3D printing doesn’t involve a blank, because it adds layers upon layers of the desired material’s powder, for completing the prototype molding process as and when necessary. The powder is periodically solidified with either an industrial-grade laser or a hot extruder, as required to finish each step of the additive layering process.

Which is Better: Additive or Subtractive?

As it is with most industrial processes, the term ‘better’ cannot be used universally, and more than anything else, it depends on the particular scenario. Check out the following list of advantages and disadvantages of both to determine if additive or subtractive methods of prototype machining make more sense in relation to your particular project.

Additive Manufacturing with 3D Printing

+ The ability to work with a wide range of shapes without losing accuracy when the design involves very complex geometry

+ Application across a wide range of industries as a result of the above

+ It’s a faster process for small scale prototype manufacturing

+ 3D printing is usually cheaper and the products are lighter

– Not the most ideal choice for large scale prototype machining

– Prototypes cannot be manufactured at the same tolerance level as those produced by CNC machining

– Limited in its ability or unable to work with sheet metal prototyping and sheet metal fabrication

Subtractive Manufacturing with CNC Machining Services

+ Superb and unmatched dimensional accuracy

+ Ability to work with harder materials such as wood and metals

+ Can be used for large prototype manufacturing projects

+ Can be utilized for injection molding services, sheet metal prototyping, and sheet metal fabrication

+ Quality of the prototype molding process makes the final products significantly better

– CNC machining services can get quite expensive for small prototyping projects and they can’t handle extremely complex geometric designs

A Comparative Overview from Every Business Angle

Although the decision should be easier to make now, hold on until we have taken a look at all the parameters from a business point of view first.

Cost-Effectiveness – 3D printing is cheaper for small orders, but not when it comes to large orders with multiple parts. The more parts that are necessary for the prototype machining process, the more expensive it will become, which is precisely what makes 3D printing particularly unsuitable for large volume orders.

On the other hand, the cost-effectiveness of online CNC services and the ease of being able to order CNC services online from reputed Chinese manufacturers at a more affordable rate has made them a lot cheaper in general, and useable for medium-sized orders. It might still be more expensive in case of small orders, but whether the quality is worth the extra cost or not is for the business to decide.

Environmental Aspect – CNC is a subtractive method of prototype manufacturing, and that means there will be waste from all that cutting and shaping. Given that most materials are easily recyclable, that should not be a problem today, but it’s true that 3D printing for rapid tooling is just more eco-friendly, since it produces minimum waste due to it being an additive manufacturing technique, especially when we are discussing plastic.

Tolerance – No 3D printing method in existence can come even close to CNC machining (including DML and FDM) as far as tolerance is concerned. CNC is unmatched for sheet metal prototyping and sheet metal fabrication, not to mention the fact that the size of the parts which CNC can handle across all materials is not something that even the most advanced 3D printing method can boast of.

Geometric Complexity – If your project involves prototype molding in complex geometric patterns, then a 3D printing method such as SLS is going to be the right choice. CNC cannot be used for extremely intricate geometric machining processes and thus it won’t be of use in such instances.

Consult the Professionals Before Making a Choice

Although the facts have been laid out now, there are plenty of other factors that also need to be taken on board before making a decision, and since that’s impossible to do without knowing the exact needs, it’s highly advised that you pay a visit to a site like Rapid Direct first, before finalizing your decision. The firm offers an online manufacturing platform, giving you access to everything you need in one place. Given that Rapid Direct offers some of the best CNC services China has to offer at an affordable price, you may be able to order prototypes with their online CNC machining services without blowing the budget.

However, the main reason why they are definitely going to be able to guide you towards the right manufacturing method is that their rapid machining and rapid tooling services include both high accuracy CNC machining, as well as the latest 3D printing technology in use today. There’s no conflict of interest here, so they should be able to provide you with estimates regarding both, as well as guide you towards the most ideal rapid prototype molding process for the project at hand.

As you can discern by now, CNC prototyping simply makes more sense for the most part, and while 3D printing has excellent potentials of its own, its application is often limited due to factors such as being able to work only with a limited set of materials for the time being. From injection molding services and sheet metal prototyping to sheet metal fabrication, prototype molding and rapid tooling, CNC does have a wider range of applications, as well as having the ability to be used on larger prototype manufacturing projects than 3D printing.

Nevertheless, 3D printing is also cheaper for the most part, and it has the advantage of being able to handle more geometrically complex projects, as already discussed. Now that all the facts have been revealed, the choice is yours, and making it in accordance with your specific prototype molding needs in mind should not be too difficult anymore, especially after getting a little expert guidance from the manufacturers themselves.