One day in the not-too-distant future, you will be able to buy a chair from Ikea, bring it home and watch it assemble itself in front of your eyes. In this same future world, if you are diagnosed with cancer, you might be injected with nano-robots that will track down and selectively kill the cancerous cells. You will feel nothing but mildly feverish in the process.

Sentient chairs and cancer-fighting robots might sound like the stuff of science fiction, but these are two very real projects that Carlos Olguin is working on in his role as the director of the Bio/Nano/Programmable Matter Group at software giant Autodesk. Founded as a quirky Californian startup in the 1980s, the company has gone from producing AutoCAD design software for 8-bit PCs to speculating on the future of programmable lifeforms.

“We are now looking at life as a design space,” says Olguin when we meet in London, in between his hectic tour of synthetic biology research outfits. “We’re trying to explore beyond the inert world and see how we can apply what has been learned from the design industries back into organic life.”

The vehicle to make such leaps takes the futuristic name of Project Cyborg, an initiative that the company describes as a “cloud-based meta-platform of design tools for programming matter”. In essence, it is a fiendishly complicated piece of software – run remotely across the web from banks of supercomputers – that makes the process of modelling, simulation and design optimisation deceptively simple, and incredibly fast.

“A modelling process that would previously have taken weeks to complete, and post-PhD level ability, can now be completed in a few seconds with relative ease,” says Olguin. “We’re trying to de-skill the technology.”

Project Cyborg’s capabilities are currently being put to the test by several institutions across a range of fields, from architectural researchers at MIT to biological scientists at Harvard. Skylar Tibbits, an architect who heads up the Self-Assembly Lab at MIT, has been working on models for structures that can assemble themselves – from nano-scale up to buildings.

Reading this on mobile? Click here to watch video

“We are looking at the ability to programme physical and biological materials to change shape, change properties and even compute outside of silicon-based matter,” Tibbits told the TED conference in February. He demonstrated a self-folding strand, 3D-printed using “smart” materials developed by Stratasys, which folds up into a cube when put into contact with water. He explained how such technology could be scaled up for infrastructural projects such as water pipe networks.

“Water pipes are fixed capacity, so if the environment changes, the ground moves or demand changes, we have to dig it all up and start from scratch,” he said. With the use of programmable materials that build and adapt themselves, the pipes could be designed to expand and contract, and even pulsate to drive water through them, mimicking the natural process of peristalsis in the human intestine. “It’s like robotics, only without wires or motors,” he said. Tibbits sees a future where this technology could be used to build anything from furniture to bikes, cars and even buildings, the process of self-assembly stimulated by different energy sources, from heating to shaking, gravity to pneumatics.

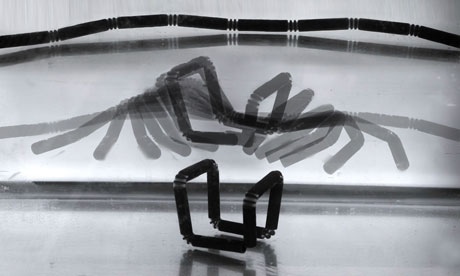

While Tibbits seems set on architectural applications, others have been looking at the scale you cannot even see under a microscope. At Harvard University’s Wyss Institute, Shawn Douglas (now at the University of California, San Francisco), Ido Bachelet and George Church have been using Autodesk’s software to build nano-scale protein structures in a process of “DNA origami”.

Reading this on mobile? Click here to watch video

“DNA is an incredibly useful structural material”, says Olguin, “because it is so predictable in the way it folds”. Douglas has developed a nano-robot built from DNA strands, in the form of a clamshell basket, with double-helix “locks” that are only opened when the robot comes into contact with specific cancerous cells. When the clamshell is opened, it releases specifically targeted antibodies that halt the cells’ growth, mimicking the behaviour of our natural white blood cells. It is a revolutionary step, which could one day do away with invasive chemotherapy treatments.

This brave new world of smart pharmacology and personalised medicine is just one of the avenues Project Cyborg is aiming to facilitate. With ongoing projects such as tracking bacteria cultures in mechanically ventilated buildings to self-assembling furniture, it could see a fundamental shift in how designers think and operate, starting from the bottom up.

“When we learn to design, it is traditionally a top-down approach of imposing our own vision,” says Olguin. “This is a different design paradigm: it is about setting the parameters and letting the material develop and evolve on its own.”

guardian.co.uk © Guardian News & Media Limited 2010

Published via the Guardian News Feed plugin for WordPress.